by laura | Sep 30, 2011 | Business & People News

The ASID Foundation has introduced a new $12,000 student scholarship. To be awarded biannually, the David Barrett Memorial Scholarship will recognize an outstanding undergraduate or graduate student’s work that demonstrates an interest and ability in utilizing...

by laura | Sep 29, 2011 | Business & People News

LG Electronics and Good Housekeeping have launched the Greener Living Tour, a national farmers market circuit designed to educate consumers on how to live healthier and greener with the help of fresh foods and efficient products. “Now, more than ever, our...

by laura | Sep 28, 2011 | Business & People News

Rev-A-Shelf has signed a Letter of Intent to acquire Tresco International Ltd. The acquisition of the Tresco International line will allow its distributors to promote the lighting products that will be shipped and supported through Rev-a-Shelf. “We are committed to...

by laura | Sep 27, 2011 | Business & People News

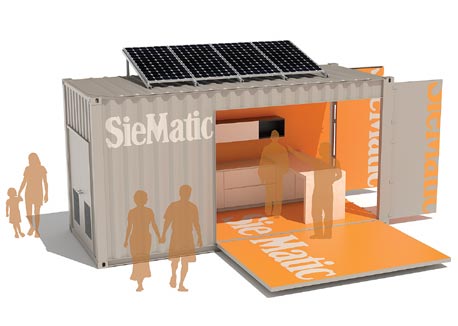

SieMatic has joined forces with Arizona Cabinet Pros to hit the road in a semi-trailer truck that showcases kitchen displays in ISO shipping containers. The displays will roll into approximately 31 metropolitan areas that are largely void of showrooms with kitchens....

by laura | Sep 27, 2011 | Business & People News

Designing an organized kitchen for the at-home chef is about more than just finding a place for all of their “stuff.” As discussed in the first half of this two-part series, it also involves asking the right questions and delving into their psychology, which will in...